Taurus Motors

High Performance Axial Flux Servo Motors with Automated Design and Manufacturing

Let us create and integrate the perfect axial flux servo motor, so you can focus on the machine it goes in.

ROBOTS AND AEROSPACE VEHICLES COME IN EVERY SHAPE AND SIZE

The performance of a robot or electric vehicle fundamentally hinges on its motors’ collective torque, power, and weight—factors which cause companies to invest significant design budgets, often exceeding $100,000 per motor design, to develop custom servo motors for each application. Taurus Motors designs and manufactures custom superior Axial Flux servo motors to meet any requirement, quickly and cost-effectively.

Sources: Boston Dynamics, Force Technology, Zipline, Carnegie Mellon Robotics Institute, NASA, FANUC

The Power of the Pancake: Axial Flux

From log to pancake…shorter length, larger diameter. More torque, more power, and less copper losses due to increased lever arm distance.

Our axial flux designs beats the industry best, pancake shaped, radial frameless motor kits by 10% to 33% torque density and 10% to 33% power density for a matching volume.

Our designs beat log shaped radial motors by 33% to 400% or more (depending on the diameter change when switching to Axial Flux).

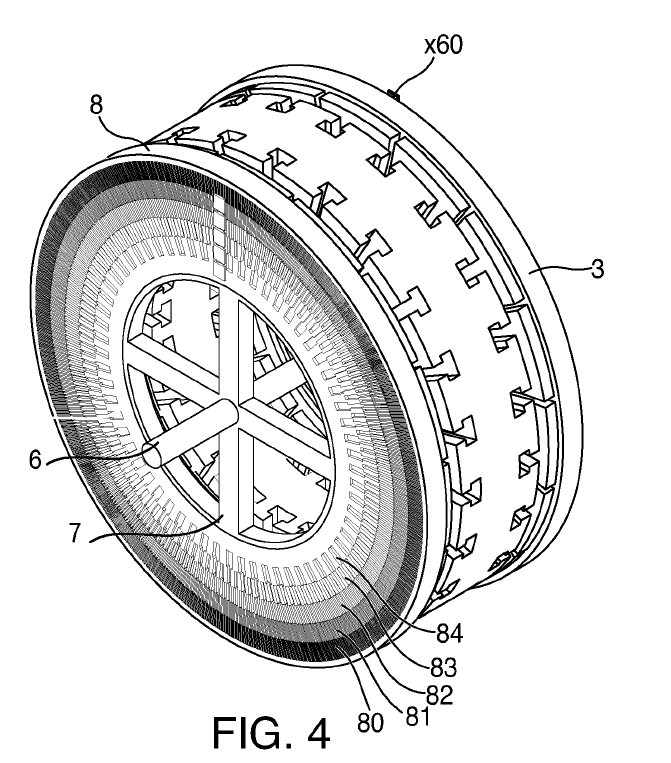

Patented Built-In Speed and Position Feedback

Our patented Axial Flux design includes an optical encoder built into the rotor for position and speed feedback without the need for a separate part.

From the tech that brought you particle accelerators and fridge magnets…

The mighty halbach array: focusing magnetic field where you need it, and canceling it where you don’t.

Automated Motor Design Combined with Rapid Prototyping

Define High Level Parameters

Our Engineers engage closely with clients to define high-level requirements like diameter, torque, speed, power, voltage, physical footprint, control and communication types, and desired accessories.

Returning customers familiar with our process will be able to specify requirements using our user-friendly website (upon launch).

Automatically generated CAD designs and CAM programs

Driven by software, CAD models are automatically generated, then CAM programs are automatically generated for your custom axial flux servo motor to be made on our machines. Engineering Simulations are run to provide predicted performance. Custom tooling designs are automatically generated. Our design toolkit minimizes design, setup and tooling costs. The motor stator and rotors are designed first. Encoders, sensors, and gearboxes are chosen. Then power switching cards, control loop cards, and communication cards are designed. A bill of materials for any accessories are generated. Designs are saved so they can be re-ordered in the future. All of our tools are designed to be compatible with Artificial Intelligence (AI) optimization algorithms.

Choose your batch size and have the parts made and ordered

Once the customer approves the final design, our team sets up machines, creates necessary tooling, and commences manufacturing of the custom motor batch. Customers are charged a setup and tooling fee for a batch, and then charged per unit. Tooling is cataloged so a customer can save money on tooling and setup if they re-order in the future. We specialize in low to medium volume orders.

Whether its a prototype, or for production, let us make the perfect axial flux servo motor for what you need. Use us to make the perfect axial flux frameless kit, to use with your favorite drives, sensors and gearboxes, or have us get you everything!