Taurus Motors

High Performance Axial Flux Servo Motors with Automated Design and Manufacturing

We deliver rapid and cost-effective designs for superior, custom Axial Flux servo motors to meet any requirement

Aerospace vehicles and robotic systems come in every shape and size.

The performance of an electric vehicle or robot fundamentally relies on the collective torque, power and weight of its motors.

These factors compel developers to invest significant time and budget in custom design, often exceeding $100,000 per motor for each application.

Taurus Motors provides rapid and cost-effective designs for superior, custom Axial Flux servo motors to meet any requirement.

The Power of the Pancake: Axial Flux

From log to pancake…shorter length, larger diameter. More torque, more power, and less copper losses due to increased lever arm distance.

Our axial flux designs beat the industry best pancake-shaped radial frameless motor kits by 10% to 33% torque density and 10% to 33% power density for a matched volume.

Our designs also beat log-shaped radial motors by 33% to 400% or more, depending on diameter change when converting to Axial Flux.

Above: A dual-rotor Axial Flux motor design. The central stator is flanked by two Halbach array disc rotors.

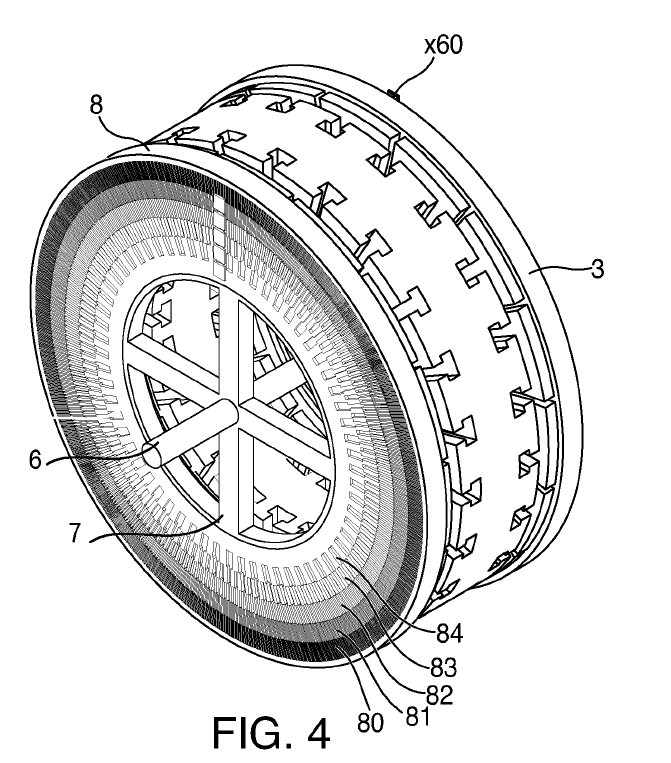

Left: Conceptual rendering of an Axial Flux motor with an additional rotor encoder disc.

Figure 4, US Patent No. 10,594,235 B2

Patented Built-In Speed and Position Feedback

Our patented Axial Flux design includes an optical encoder built into the rotor for position and speed feedback, eliminating the need for a separate part.

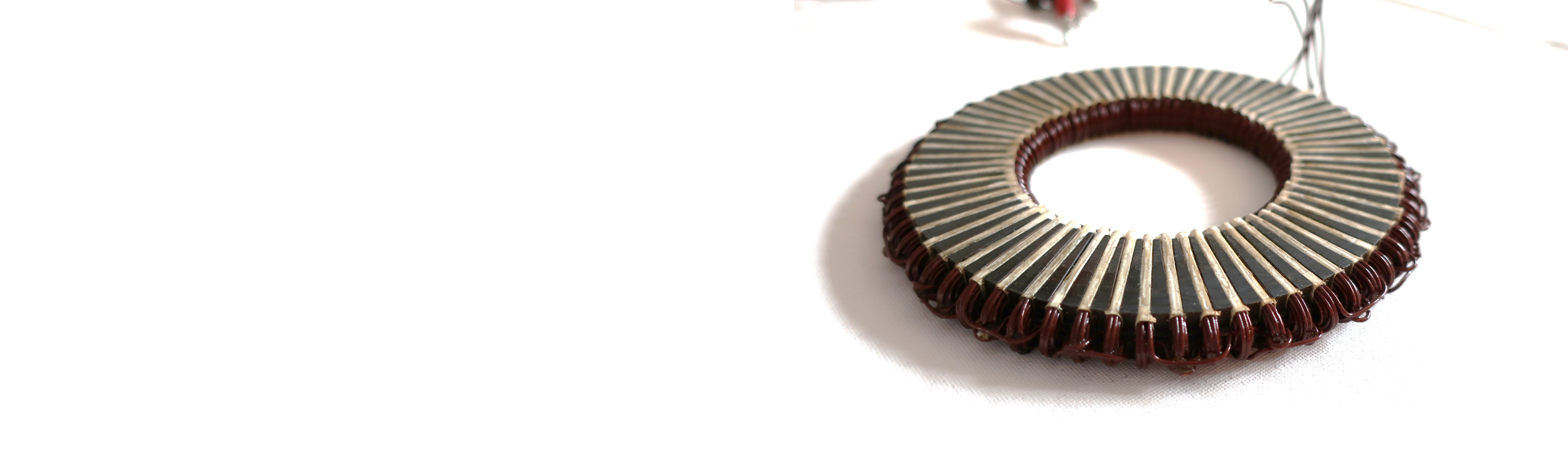

Halbach array rotor

From the tech that brought you particle accelerators and fridge magnets…

The mighty Halbach array focuses magnetic field where you need it, and cancels it where you don’t.

Above left: Conceptual rendering of a Halbach array rotor for an Axial Flux motor design. Above right: A prototype rotor with attached magnets.

We offer Automated Motor Design for Rapid Prototyping

Define Your Specifications

Please contact Taurus Motors directly to inquire about motor design services or case study collaborations.

Our engineers engage closely with customers to define high-level requirements like diameter, torque, speed, power, voltage, physical footprint, control and communication types and desired accessories.

In the future, returning customers familiar with our process will be able to specify requirements using a user-friendly website (upon launch).

We Auto-Generate the Design

We use our highly parameterized tool to automate the Axial Flux motor design process. Using this rapid design tool, we automatically generate CAD models and also CAM programs for your custom Axial Flux servo motor. ANSYS simulation files are also created, and engineering simulations can be run to provide predicted performance.

Overall, our design tool can save our customers significant time and budget on Axial Flux motor development. We design motor stator and rotors first, followed by selection of encoders, sensors, and gearboxes. Next, we design the power switching cards, control loop cards, and communication cards. Designs are saved so they can be re-ordered in the future.

The Future: Rapid Manufacturing

We currently specialize in low volume manufacturing in which we provide point-of-contact support for the production of components from preferred vendors. Please contact Taurus Motors for more information about in-house prototyping or potential manufacturing workflows.

Because we can also automate custom tooling designs, we aim to expand our toolkit in the future to include an automated setup and tooling workflow. Once the customer approves the final design, our team would set up machines, create the necessary tooling, and commence manufacturing of the custom motor batch. Tooling can be cataloged such that customers save money on tooling and setup if they re-order in the future.

Overall, our complete design toolkit will minimize design, setup and tooling costs. All of our tools are designed to be compatible with Artificial Intelligence (AI) optimization algorithms.